Distribution centers are the backbone of modern supply chains, ensuring products move seamlessly from manufacturers to customers. Whether you’re managing a small facility or a massive warehouse, understanding the essentials of an efficient distribution center is critical. From organization and safety to technology and staffing, every aspect contributes to smooth operations.

1. Efficient Layout and Space Utilization

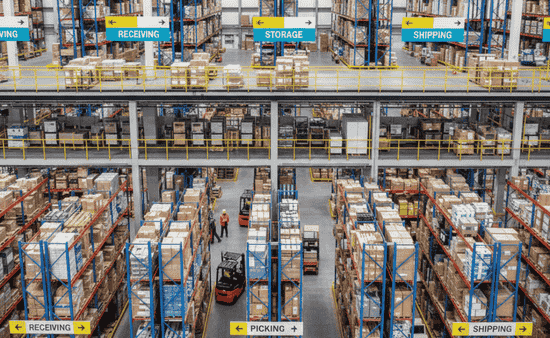

The foundation of a successful distribution center is its layout. An optimized design minimizes travel time for employees and reduces bottlenecks in product movement. Consider zoning areas for receiving, storage, picking, packing, and shipping. Narrow aisles may increase storage capacity but can slow down forklifts. Balance space efficiency with workflow speed.

Using racking systems, mezzanines, and pallet positions strategically ensures every square foot is utilized effectively. Don’t forget the importance of clear signage—it guides staff, reduces errors, and keeps the workflow smooth.

2. Inventory Management Systems

An effective inventory management system (IMS) is non-negotiable. Accurate tracking of stock levels, product locations, and order statuses reduces the risk of lost or misplaced items. Modern IMS solutions integrate with barcode scanners, RFID technology, and warehouse management software (WMS) to provide real-time insights.

Automated alerts for low stock levels or expired products allow for proactive management, reducing costly downtime and improving customer satisfaction.

3. Essential Equipment and Tools

A distribution center relies on the right equipment to maintain efficiency. Forklifts, pallet jacks, conveyor belts, and carts are standard, but specialized tools can enhance operations. For instance, using plastic dunnage helps protect products during transport and reduces damage, while lightweight carts and ergonomic lifting tools can improve worker safety and productivity.

Don’t overlook basic but essential items like packing materials, labeling machines, and barcode scanners—these small tools significantly impact day-to-day efficiency.

4. Workforce Training and Safety

A well-trained workforce is essential for smooth operations. Employees must be familiar with equipment, safety protocols, and workflow procedures. Regular training sessions not only reduce accidents but also improve speed and accuracy.

Safety equipment like gloves, helmets, high-visibility vests, and proper footwear is a must. Clear safety signage, emergency protocols, and routine drills create a culture of safety that benefits everyone.

5. Technology Integration

Technology has transformed distribution center management. Warehouse management systems, automated picking solutions, and AI-driven analytics help streamline operations and forecast demand. Integration with transportation management systems (TMS) ensures orders move efficiently from the warehouse to the customer.

Investing in technology can reduce human error, optimize space usage, and provide actionable insights for continuous improvement.

6. Performance Metrics and Continuous Improvement

Monitoring key performance indicators (KPIs) keeps your distribution center operating at peak efficiency. Metrics like order accuracy, inventory turnover, picking speed, and shipping time identify areas for improvement.

Continuous improvement is a mindset. Encourage staff feedback, conduct regular audits, and implement process enhancements based on data. Even small changes, like reorganizing high-demand products near packing areas, can significantly impact productivity.

7. Sustainability and Maintenance

Sustainability is increasingly important in distribution operations. Using energy-efficient lighting, reducing packaging waste, and implementing recycling programs contribute to eco-friendly practices.

Routine maintenance of equipment and infrastructure prevents breakdowns that can halt operations. Scheduled inspections, preventive maintenance, and immediate repairs keep your distribution center running smoothly.

In Conclusion

Running an efficient distribution center requires careful planning, the right tools, trained staff, and continuous optimization. From layout and inventory management to safety, technology, and sustainability, every element plays a role in keeping operations seamless. By focusing on these essentials, you can maximize efficiency, reduce errors, and meet customer expectations consistently.

Investing in the right infrastructure, equipment, and workforce training today sets your distribution center up for long-term success tomorrow.